In the chemical industry, the precise management of every high-value piece of equipment and every dedicated container directly impacts production safety, operational efficiency, and cost control.

For the global Fortune 500 chemical giant BASF, whose business spans the globe, assets are vast, and management scenarios are complex; achieving transparent, refined, and intelligent asset management is a key step on its digital transformation path. RFID technology is exactly the major step BASF has taken to raise its management level.

– BASF’s enterprise management pain points & needs –

As a world-leading chemical company, BASF has extensive operations and a massive asset scale, placing extremely high demands on refined, visualized, and process-oriented asset management. How to achieve efficient control of assets across regions and scenarios has become a vital issue in BASF’s digital-transformation journey:

Lack of asset visualization: tens of thousands of assets are distributed across different plants and warehouses; traditional management methods have long update cycles, asset status is unclear, and position is untracked.

Low inventory efficiency: information transmission depends on manual documents, physical inventory takes time and effort, accuracy is low, and traceability is difficult.

Information silos: asset procurement, warehousing, usage, maintenance, and disposal workflows are not deeply integrated with the OA approval system.

Faced with BASF’s pain points of traditional asset management relying on manual work, discrepancies between records and reality, and disconnected processes, DTB RFID partnered with Weaver to jointly build an RFID-asset smart management solution deeply integrated into the Weaver OA system. This was not only a technological upgrade but also a revolution in management thinking.

– Seamless transition from the old system to the upgraded state –

– Custom-made deep integration –

Customized system integration capability, seamless connection to the Weaver OA

Considering that BASF already had an asset management system in place, adapting a new system from scratch would be costly and time-consuming. DTB RFID selected a software form that better suited the enterprise:

DTB RFID’s self-developed RFID asset-management module was seamlessly embedded into the Weaver OA platform used by BASF. RFID technology nodes (such as scanning for usage and inventory) were tightly bound to OA approval flows. Employees could complete all asset operations within the familiar OA interface, achieving “one platform, unified management,” with minimal cost and disturbance to process redesign and optimization.

Robust labels and device support to guarantee frontline data capture

In actual deployment, DTB RFID supplied matching RFID tags and RFID hardware devices based on BASF’s asset status, as reliable support for first-line data capture:

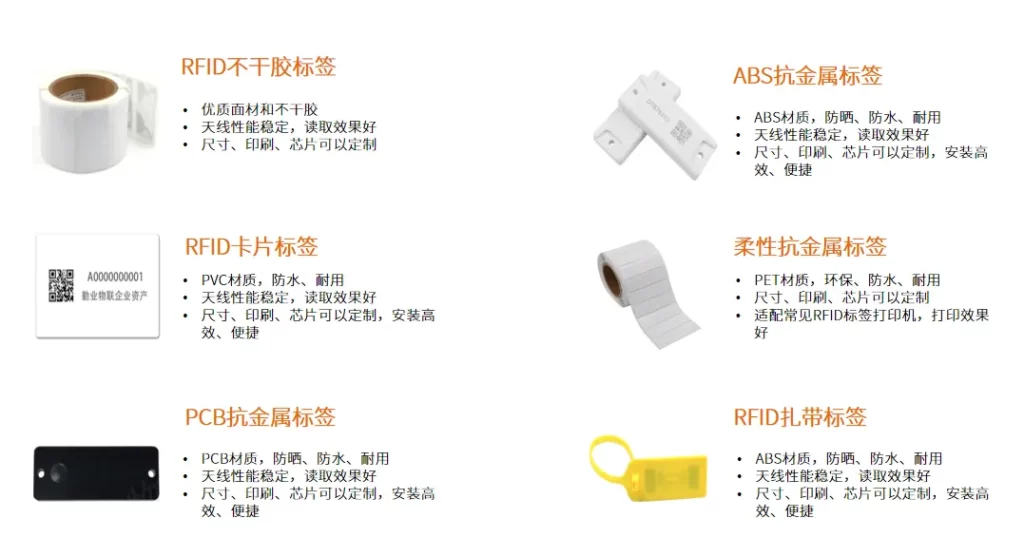

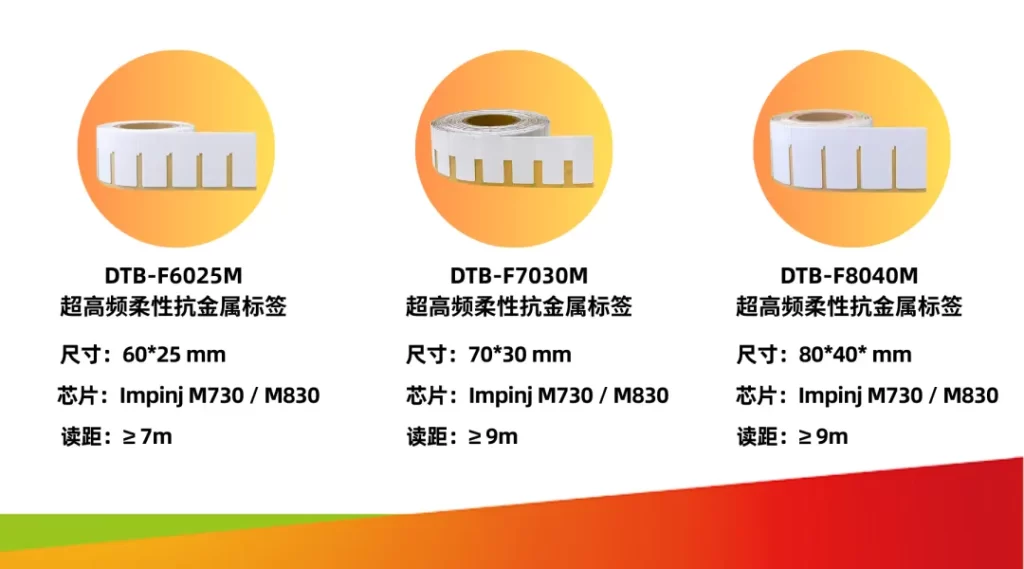

RFID tags: Using adhesive tags and flexible-resilient tags, covering non-metal and metal office assets and equipment, enabling single-item asset management; paired with hardware devices to effectively enhance management accuracy.

RFID hardware devices: Provided RFID industrial printers and intelligent handheld terminals, enabling staff to efficiently print labels and inventory assets in bulk.

Following deployment, DTB RFID successfully helped BASF apply RFID technology in asset management, achieving full lifecycle management of assets. The company’s asset utilization rate improved by an average of 65 %, and contactless, second-level bulk inventory freed the company entirely from time-consuming, labor-intensive traditional inventory models.

– RFID asset-management solution –

– Upgrade your existing asset-management system with one click –

Since the rollout of the DTB RFID asset-management solution, a rich deployment experience has been accumulated across enterprises nationwide. Not only can it provide a full suite of hardware and software solutions for enterprises starting from zero, but it can also offer customized integration with OA and other systems for enterprises with foundations already in place.

From enterprise needs and actual conditions, the full process of solution planning, deployment, and after-sales service is followed through. Matching is customized according to enterprise subject, asset type, asset quantity, and management requirements, providing each enterprise with the most suitable and efficient asset-management solution!