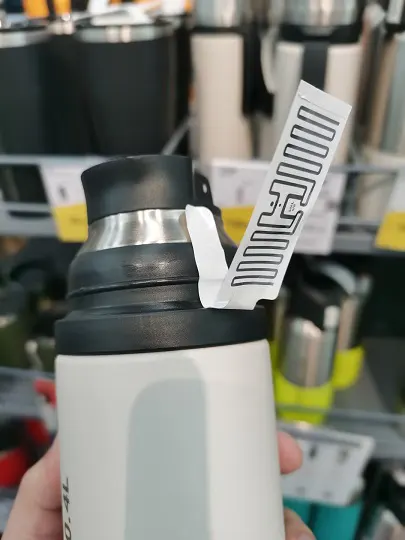

Deploying RFID in real-world environments is far more challenging than product brochures or marketing demos suggest. In controlled demonstrations, tags respond instantly, read rates look perfect, and system reliability seems guaranteed. However, once RFID moves into environments dominated by metal racks, liquid containers, or mixed industrial assets, performance often changes dramatically. Warehouses with steel shelving, production lines surrounded by machinery, and storage areas full of liquid drums reveal challenges that early testing rarely uncovers.

The issue is not that RFID is inherently unreliable—it is that radio frequency behavior is deeply shaped by its surroundings. Metal surfaces reflect and distort RF signals, while liquids, especially water-based substances, absorb energy and reduce transmission. Ignoring these constraints can lead to overcompensation with higher reader power, aggressive filtering, or manual intervention. Over time, accuracy declines, trust erodes, and RFID is perceived as a technology that “promised much but delivered inconsistently.”

Understanding Environmental Constraints in Metal and Liquid RFID Deployments

Many RFID projects appear successful in pilots but fail when deployed in metal- or liquid-rich spaces. The root cause often lies in planning: teams focus on software integration or data visualization before fully evaluating physical conditions. RF behavior is shaped by surface materials, spacing, orientation, and movement patterns. Treating these as secondary concerns often results in designs that do not survive real-world operations.

Lab testing can give a false sense of security. A tag that works well on a cardboard box may perform poorly when attached to curved metal, placed near liquid containers, or exposed to vibration and temperature changes. For instance, in a warehouse with dense steel shelving, a UHF tag placed directly on metal without ferrite insulation may only achieve a 40–50% read rate, while a properly spaced flexible anti-metal tag can reach 95% or higher. Similarly, HF tags near liquid bottles may fail if placed on the broadest surface of the container, but perform reliably when positioned on the neck or non-liquid-facing side.

Real-world deployments show that even minor environmental changes—like adding a metal pallet jack or stacking plastic crates differently—can shift read zones and affect accuracy. Successful projects include environmental mapping as part of early planning, noting where reflections or absorption may occur, and predefining safe placement zones for tags.

Choosing the Right RFID Frequency and Chip Type

Selecting the right frequency and chip is crucial.

· High-Frequency (HF) RFID often outperforms expectations in liquid-heavy environments due to its inductive coupling mechanism. HF tags on anti-liquid labels maintain stable reads even near water-based solutions, such as pharmaceutical bottles, laboratory samples, or cosmetic containers. Chips like NXP NTAG216 are commonly used for their reliability and memory capacity, providing consistent performance across multiple reads. HF is particularly suited for workflows requiring close-proximity scanning of individual items, such as quality checks or small container tracking.

· Ultra-High-Frequency (UHF) RFID provides longer read ranges and faster bulk scanning but is highly sensitive to metal and liquid interference. In metal-heavy environments, combining UHF chips like Impinj Monza R6-P with flexible, PCB, or ABS anti-metal tags significantly improves read stability. These tags mitigate detuning effects caused by metal and maintain resonance over repeated scans.

· Selection between HF and UHF also depends on the workflow: HF is ideal for item-level scans, while UHF is suitable for pallets, cases, or conveyor-level bulk scanning. For liquid-heavy environments, anti-liquid tags should be positioned thoughtfully, avoiding the densest portion of the liquid, such as placing tags on container necks or non-liquid-facing sides.

Field data shows that HF anti-liquid tags achieve nearly 98% read reliability within 10 cm of water-based liquids, while standard HF tags in the same environment drop below 60%. For UHF, performance can improve from 50% to over 90% by choosing PCB or ABS anti-metal tags and properly spacing them from metal surfaces.

Tag Design and Placement Are Critical

Tag design is not just a procurement decision; it is a foundational engineering choice. In metal or liquid environments, flexible, PCB, or ABS anti-metal tags and anti-liquid tags are engineered to maintain RF performance despite challenging conditions.

Placement is equally critical. Metal surfaces create reflection zones and dead spots, especially near edges, corners, and enclosed cavities. Even minor adjustments—a few millimeters of spacing—can significantly improve read stability. In industrial tool tracking, placing flexible anti-metal tags on the back of curved tools versus the top surface can change the read success rate from 65% to over 90%.

Human behavior also plays a role. Operators rotate containers, stack boxes inconsistently, or place items wherever there is space. Successful deployments anticipate variability, establishing placement standards, visual guides, or mechanical fixtures to ensure predictable tag orientation. In a logistics center, visual alignment markers improved compliance and read rates by over 15% without additional hardware investment.

Other practical tips include:

· Avoid placing tags in corners or near edges where reflections are strongest.

· For containers, place tags on the side with minimal liquid or opposite the heaviest metal surface.

· In multi-level shelving, ensure tags on lower layers do not shield those above from the reader’s signal.

Reader Configuration and Antenna Design

Increasing reader power is often counterproductive in metal-heavy environments. Higher power amplifies reflections, creating overlapping read zones and ghost reads. Directional antennas are more effective, focusing energy into defined zones and reducing unintended reflections.

Reader and antenna placement should consider workflow patterns. For instance, placing UHF readers above conveyor choke points where items naturally pass can provide stable reads without relying on brute-force power. Flexible anti-metal tags pair well with directional antennas, while anti-liquid HF tags may require loop or ring antennas positioned near container necks. Adjusting read angles and polarization further enhances performance.

In one medium-sized manufacturing plant, adjusting reader angles by 15 degrees and adding ferrite shielding behind PCB anti-metal tags increased read rate from 72% to 95% across a mixed-metal workstation.

Designing Read Zones That Match Human Workflows

RFID failures often stem from workflow mismatches rather than RF physics alone. If operators do not understand read zone boundaries, they may slow down, rescan, or revert to manual checks, eroding confidence in the system.

Effective deployments make read zones visible and intuitive. Physical markers, consistent placement rules, and simple handling instructions help align human behavior with RF constraints. In metal enclosures, RF-transparent sections or openings are sometimes required to enable accurate reads. For example, cutting small RF windows in cabinet doors for PCB anti-metal tags improved read rates from 60% to over 90% without changing hardware.

Additional practical steps include:

· Use colored tape or markers to show read zones.

· Train operators on proper placement and handling.

· Include workflow steps in SOPs to prevent ad-hoc positioning of tagged items.

Environmental Variables That Change Over Time

Metal and liquid challenges are dynamic. Temperature shifts affect adhesives and tag tuning; humidity changes material properties; vibration and mechanical stress degrade performance. Tags that work perfectly at installation may slowly lose accuracy if environmental changes are not monitored.

Periodic verification is essential. Reviewing tag placement, checking reader alignment, and documenting environmental conditions help maintain long-term stability. Multi-site logistics deployments showed that routine inspections every six months maintained over 95% read reliability across thousands of items. Maintenance is not a weakness—it reflects a realistic understanding of RFID physics in complex environments.

Other considerations:

· Liquid-filled containers may expand or contract with temperature, slightly shifting tag position.

· Metal machinery may be added or removed, changing reflection patterns.

· Periodic audits should include sample reads in all areas to detect emerging dead zones.

Pilot Projects and Avoiding False Confidence

Small pilots often succeed under ideal conditions that do not scale. Limited asset counts, careful placement, and attentive operators create controlled success. Full-scale deployments introduce denser storage, faster handling, and greater variability, exposing system weaknesses.

Effective pilots include worst-case scenarios: full metal density, maximum liquid volumes, and realistic operator behavior. Early identification of limitations allows teams to redesign layouts, adjust tag placement, or recalibrate reader settings before large-scale rollout. Software analytics can highlight patterns but cannot replace proper RF-aware deployment planning.

What Works in Metal and Liquid RFID Deployments

Across industries, successful deployments share a common trait: they respect environmental constraints. Examples include:

· Industrial tool tracking: flexible anti-metal tags placed on accessible surfaces combined with directional antennas maintain stable performance.

· Liquid-heavy production lines: anti-liquid HF tags placed on container necks or non-liquid-facing sides outperform aggressive bulk scanning strategies.

· Metal cabinets or racks: PCB or ABS anti-metal tags achieve high read rates when combined with optimal spacing, antenna alignment, and proper workflow integration.

· Multi-layer pallet storage: careful combination of tag orientation and reader placement can reduce missed reads from over 20% to below 5%, improving inventory accuracy.

· Laboratory sample storage: HF anti-liquid tags near small vials maintain over 98% read accuracy when placed away from dense liquid columns.

Predictability—not raw read rate—is the key to operational trust and long-term adoption.

Final Perspective

RFID does not fail in metal or liquid environments because it is unreliable. It fails when teams expect it to behave like a neutral sensor. Projects that accept physical constraints early and design accordingly succeed. Attempts to compensate later with software, power, or procedural tweaks rarely fully resolve the issue.

Respecting the environment is not a limitation—it is the foundation of every RFID deployment that actually works. Real-world success comes from combining proper tag selection, chip type, antenna configuration, placement strategy, and workflow alignment.