When tens of thousands of pallets and turnover boxes circulate through the supply chain, logistics operators often face three major challenges:

Unclear asset whereabouts

Inefficient manual inventory

Disorganized circulation data

Traditional barcode systems are prone to wear, human error, and inaccurate billing, becoming bottlenecks that hinder operational efficiency. So, how can logistics enterprises use RFID technology to achieve a true digital upgrade? Let’s explore how DTBRFID partnered with CIMC to transform carrier management.

The Challenges of CIMC’s Carrier Management

Pain Points in Traditional Operations

As a global leader in logistics equipment with over 20 years of expertise in unitized logistics carriers, CIMC manages tens of thousands of pallets, bins, and containers. However, barcode-based management could no longer keep up with business expansion:

Barcodes often wear out or fall off during frequent circulation, leading to missed or inaccurate counts.

Barcode inventory requires one-by-one scanning, which consumes excessive time and labor as carrier volumes grow.

Long inventory cycles delay verification during asset recovery, resulting in low return rates, higher losses, and poor traceability.

With business scaling rapidly, CIMC urgently needed a modernized, more reliable solution for carrier management.

Customized RFID Upgrade: Reshaping the Digital DNA of Carriers

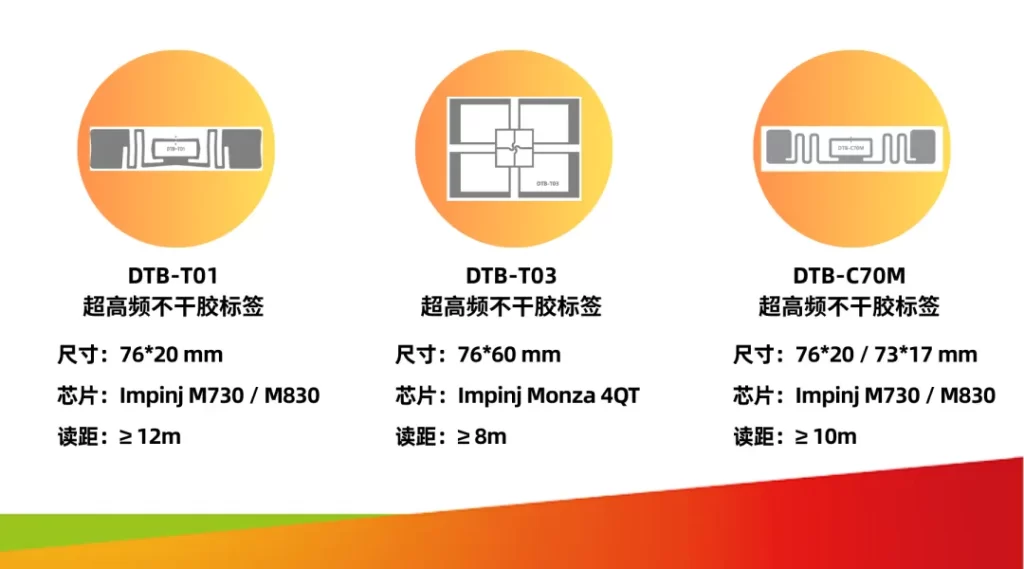

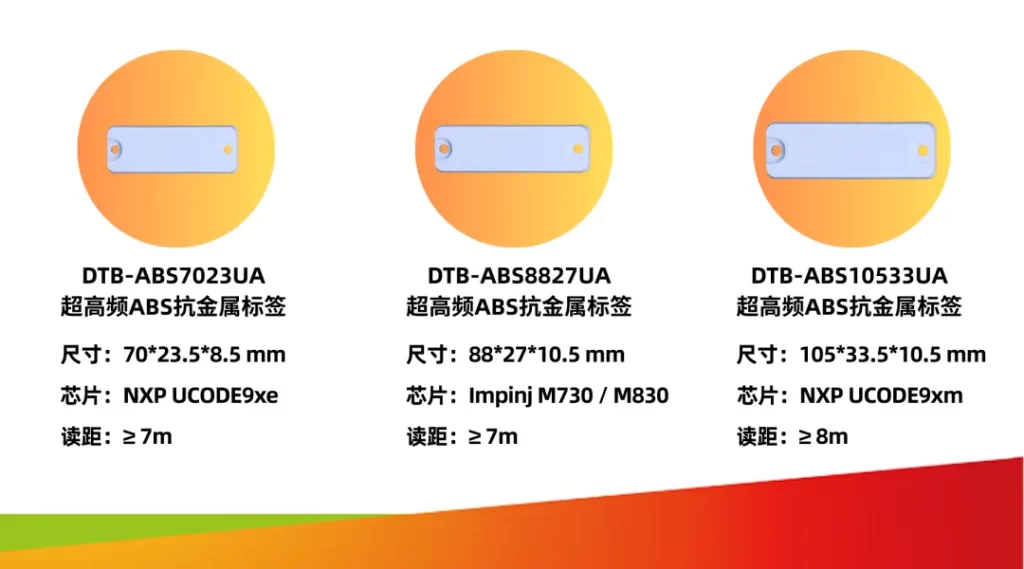

After carefully analyzing CIMC’s operational needs, DTBRFID proposed an RFID-driven solution—offering three categories of tags and supporting hardware tailored to logistics scenarios:

RFID Labels

Widely applicable, cost-effective, and suitable for most standard scenarios

Easy to deploy—just stick and go

Designed to resist metal interference, ideal for pallets, racks, and metallic carriers

Built with industrial-grade durability for long-term use

RFID Card Tags

Lightweight, slim, and available in multiple sizes to fit diverse carriers

Resistant to wear and impact, perfect for high-frequency transport environments

RFID Handheld Terminals

Reading range of over 20 meters with contactless, batch-level scanning in seconds

One-click data upload to back-end systems, dramatically improving inventory efficiency

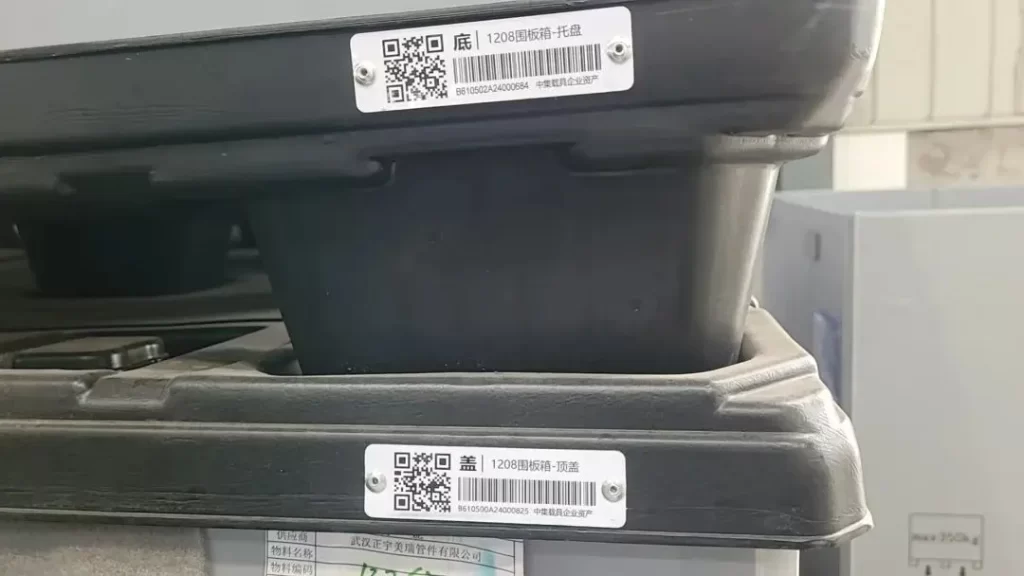

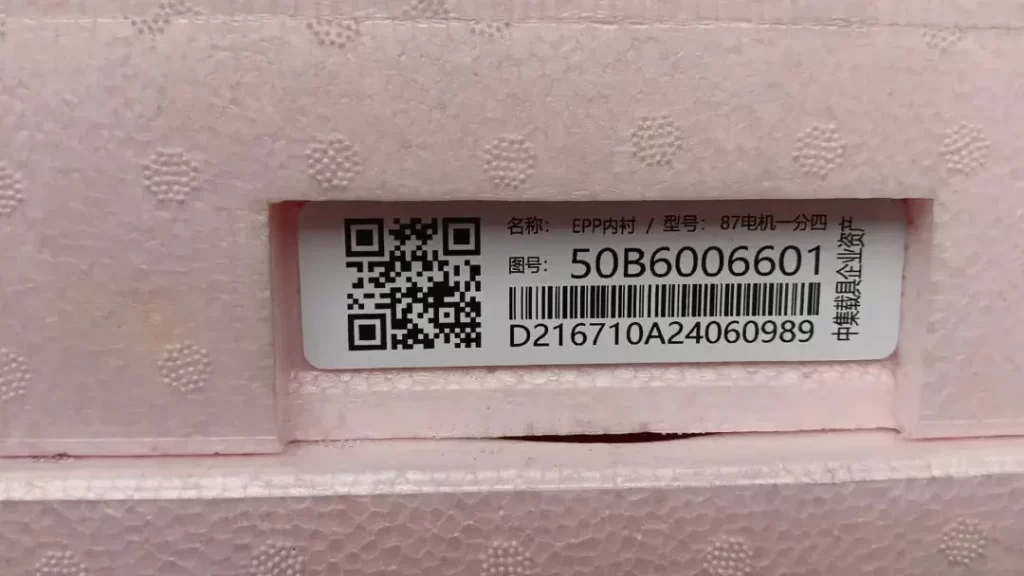

Additionally, all tags support custom printing, allowing QR codes, barcodes, or product numbers to be displayed on the surface for hybrid use cases.

Efficiency Revolution: From Blind Spots to Full Visibility

CIMC Group label example

By transitioning from barcode-based to RFID-based management, CIMC achieved a qualitative leap in efficiency and control:

30% faster inbound/outbound processing

60% higher inventory efficiency with batch scanning

50% reduction in asset loss through real-time visibility of carrier status (in-transit, in-storage, leased)

With electronic tags automatically collecting circulation data, CIMC now enables end-to-end traceability of every single carrier—from production and leasing to transportation and recovery.

DTBRFID RFID Carrier Management Solution

DTBRFID’s integrated RFID carrier management solution seamlessly connects warehousing, inventory, and transfer processes, enabling carriers to “speak for themselves.” This transparency empowers logistics enterprises to shift from experience-driven to data-driven management models.

By combining customized RFID tags, intelligent hardware, and management software, DTBRFID helps companies like CIMC achieve true digital transformation—reducing blind spots, enhancing asset control, and maximizing operational efficiency.