Jewelry stores handle high-value, small-sized, and easily misplaced or stolen items, making inventory management, security, and operational efficiency top priorities. Traditional manual tracking and inventory systems are not only labor-intensive but also prone to errors.

RFID technology offers a cutting-edge solution that transforms how jewelry retailers manage assets, inventory, and sales operations.

This article explores a full-spectrum RFID management solution tailored for jewelry stores.

1. RFID in Jewelry Management

RFID uses electromagnetic fields to automatically identify and track tags attached to objects. Unlike barcodes, RFID does not require line-of-sight scanning, allowing for bulk reading, real-time tracking, and enhanced security.

In jewelry retail, RFID can be used to:

Track individual items such as rings, necklaces, bracelets, and watches

Automate inventory audits

Enhance anti-theft systems

Improve sales efficiency by associating items with customers quickly

Provide analytics for decision-making

2. Components of a Jewelry RFID Management System

A comprehensive RFID solution typically includes:

RFID Tags: Customized to fit discrete parts of jewelry items

RFID Readers: Handheld and fixed-position devices used at display counters, storerooms, and exits

RFID Antennas: For wider coverage, especially at entrance/exit gates

Software Platform: For inventory management, POS integration, and reporting

Integration Layer: Connecting to ERP, CRM, or security systems

3. What to Tag and How

a. Tagging Different Jewelry Items

Each jewelry item requires a different tagging strategy to ensure the tag remains secure, readable, and discreet:

Rings: Tagging is done using a loop tag (like a paper or plastic string tag) where the RFID inlay is embedded in a small paper flag attached to a flexible string loop. The tag is wrapped around the ring band.

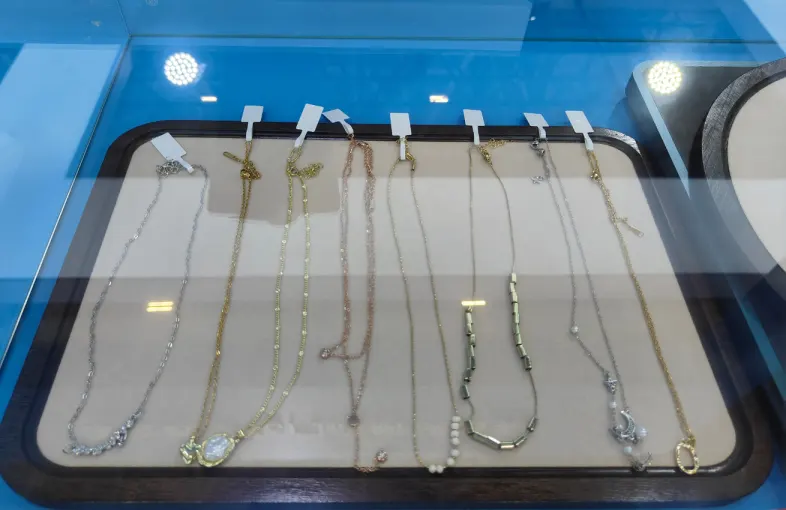

Necklaces & Bracelets: Similar loop tags are used, usually attached to the clasp or near the chain’s lock mechanism to prevent interference with customer handling.

Earrings: If sold in pairs, earrings are usually tagged as a set on a small display card that has an embedded RFID tag.

Watches: RFID hard tags can be attached to the watch strap (often using a tamper-evident seal), or embedded into the watch pillow if displayed in a box.

Gold Bars or Coins: These are typically stored in small plastic bags or cases with an RFID sticker label attached on the surface.

b. Tag Specifications

Size: Must be small and lightweight, typically between 10mm–30mm depending on item type

Memory: Minimum 128 bits EPC memory to encode SKU, item type, price, and batch info

Type: UHF (860-960 MHz) passive RFID tags are most commonly used due to low cost and longer read range (up to several meters)

Material: Jewelry RFID tags are made with non-metallic, tamper-evident materials to avoid interference.

4. Operational Workflow with RFID

a. Tag Encoding and Initialization

Each new jewelry item received at the store is tagged with an RFID label that is encoded with product details such as:

SKU

Item description (e.g., “18K Gold Ring with Ruby”)

Serial number

Date of entry

Price

Supplier

The RFID reader is used to encode and verify the tag before placing the item in the showcase.

b. Daily Inventory Checks

With a handheld RFID scanner, a single staff member can perform a complete store-wide inventory in minutes:

Walk through the display counters

Scan all tagged items in bulk (no line-of-sight needed)

Instantly compare scanned items with the digital inventory

This replaces manual counting, which is time-consuming and error-prone.

c. Display and Sale

When a customer views or tries on an item:

The salesperson scans the RFID tag

Item info pops up on the POS system or tablet

The item is temporarily registered as “out of display.”

If sold, the system updates the inventory in real time; if not, it is returned to “in stock” status.

d. Anti-Theft Integration

RFID gates at store entrances and exits can detect if a tagged item is leaving the store without checkout.

RFID tags are integrated into Electronic Article Surveillance (EAS) systems

Items sold are deactivated via the RFID deactivation module

Unauthorized removal triggers an alarm

This significantly reduces shrinkage and enhances security.

e. Stock Replenishment and Transfer

Items moved between branches or from the warehouse to the store are scanned in batches and verified automatically. Misplaced or missing items are flagged instantly, and movement history is logged.

5. Case Study: Chow Tai Fook

Chow Tai Fook, a major jewelry retailer with thousands of locations across Asia, implemented an RFID inventory system across its supply chain and retail stores.

Implementation Highlights:

Over 2 million jewelry items were RFID-tagged

UHF RFID loop tags were developed specifically for their luxury items

Staff used handheld RFID readers to perform daily inventory audits that took less than 30 minutes, compared to hours using traditional methods

Integration with their backend ERP system allowed real-time data analytics

Results:

Inventory accuracy improved to over 99.5%

Stock-taking time was reduced by 85%

Shrinkage dropped significantly due to better tracking

Enhanced customer experience by enabling faster sales processing

6. Challenges and Best Practices

Metal Interference: Jewelry metals can affect RFID performance; test tag placements carefully.

Tag Aesthetics: Choose discreet, brand-consistent tag designs.

Staff Training: Ensure all employees understand how to use RFID equipment and follow tagging protocols.

Data Accuracy: Maintain clean data input to avoid duplication and false reads.

Conclusion

By carefully planning tag deployment, integrating with backend systems, and training staff, any jewelry store—from boutique outlets to large chains—can realize the full potential of RFID.