In any RFID deployment, one of the most crucial design decisions is choosing whether to rely on stationary units, portable devices, or a combination of both. At first glance, they appear to do the same thing—read and sometimes write tag data—but in practice, each plays a distinct role. A poor choice can lead to missed reads, bottlenecks, or unnecessary labor costs. A well-planned one, however, creates an invisible backbone for efficient tracking, inventory control, and automation.

This article explains how each type of reader functions, compares their operational traits, explores real-world applications, and highlights how a hybrid approach often yields the best performance.

How Each System Works

Before drawing comparisons, it’s useful to understand what these devices consist of and how they operate.

At their core, all RFID readers share the same building blocks: a radio transceiver, an antenna or antenna ports, a control processor, and a connection—wired or wireless—to a host or backend system. The reader emits radio waves to power passive tags or communicate with active ones, receives the return signal, decodes it, and passes the tag data to software or middleware.

The key difference lies not in communication protocols—both types typically use the same standards, such as UHF Gen2 / RAIN RFID—but in their power source, mobility, and installation method.

Stationary units are permanently mounted on walls, portals, conveyor belts, or dock doors. They connect to constant power and network lines, often supporting multiple antennas to cover defined areas.

Portable devices run on batteries and are designed for mobility. They combine the radio and antenna in a handheld form, typically including a display, keypad, and wireless connectivity such as Wi-Fi or Bluetooth. Because they move with operators, their design must emphasize comfort, battery endurance, and user feedback.

Behavioral Differences

These design distinctions create fundamentally different behaviors in the field.

Continuous vs. On-Demand Scanning

Stationary systems usually scan continuously within their zones. Portable ones rely on operators to trigger scans manually or perform short bursts of activity.

Coverage and Control

Fixed installations can be precisely tuned—through antenna placement, RF power, or shielding—to monitor defined choke points. Mobile units depend on the operator’s movement and orientation, making coverage more variable.

Throughput and Tag Density

Permanent readers are optimized for large-scale operations, processing hundreds or thousands of tags per second. Handheld tools handle smaller loads and may struggle with orientation or motion in high-density environments.

Power and Uptime

Wired systems run continuously without interruption. Battery-powered ones must manage energy carefully, alternating between sleep and active modes.

Operator Dependence

Stationary equipment functions autonomously once installed, while portable tools rely entirely on human handling and discipline.

These differences affect not only read performance but also overall labor requirements, cost, and system reliability.

Strengths and Weaknesses Compared

Deployment and Infrastructure

Installing fixed units requires planning—surveying, cabling, mounting, and tuning—resulting in higher upfront cost and complexity. Portable devices, by contrast, need little setup and can be used immediately, making them ideal for small or dynamic sites.

In short, fixed systems demand more investment but deliver stable coverage; handhelds are fast to deploy and easy to move.

Range and Reliability

Stationary equipment generally offers better range and sensitivity due to higher transmit power and large antennas. In challenging environments with metal or liquid interference, they maintain consistent performance.

Portable units, limited by battery and antenna size, typically provide shorter range. Operator movement can lead to occasional missed reads.

Flexibility and Scalability

Mobile readers excel in adaptability. When a facility layout changes, they need no reinstallation—staff can simply move with them. Stationary networks, on the other hand, scale efficiently in large, stable operations, where expanding coverage means adding antennas rather than labor.

Labor and Workflow

Automated fixed readers eliminate much of the manual scanning process, while portable devices require active human participation—walking, aiming, and verifying. Yet they also serve an important corrective function: operators can use them to locate missed tags or resolve exceptions.

Cost and ROI

Fixed infrastructure entails higher capital expense but low marginal cost per read once running. Portable systems are cheaper to start with but carry ongoing costs for batteries, labor, and maintenance. In most cases, a hybrid setup—stationary for automation and mobile for audits—offers the most balanced ROI.

Practical Applications

Warehousing and Logistics

Warehouses rely heavily on RFID for tracking pallets, cases, and goods.

Dock doors and conveyors: Permanent readers automatically capture tags as shipments move through, reducing manual effort and increasing throughput.

Inventory and picking: Mobile readers allow staff to verify shelf stock or locate misplaced items.

Forklift integration: Compact readers mounted on vehicles combine the reach of fixed systems with the flexibility of handhelds.

Exception handling: If a tag is missed at a gate, an operator can quickly rescan with a portable unit.

The most effective warehouse setups use both—automation for flow, mobility for precision.

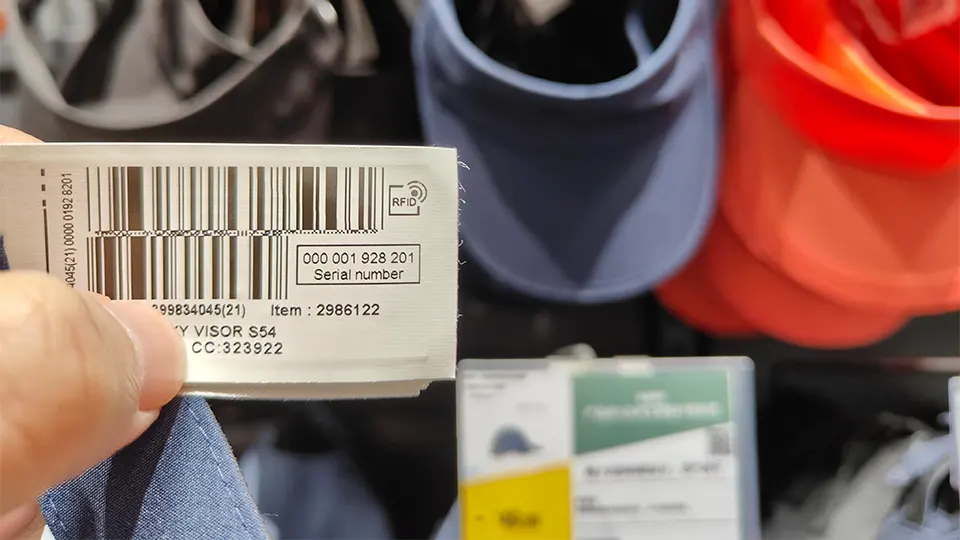

Retail and Store Management

In retail, RFID supports both customer experience and operational efficiency.

Security and exit gates: Fixed antennas detect unauthorized item removal.

Self-checkout or basket scanning: Portals that read multiple items at once speed transactions.

Shelf audits: Staff use portable scanners to verify stock levels and pricing.

Item location: Search modes help locate a specific item using signal strength feedback.

Larger stores often combine both types, while smaller shops may rely solely on handheld devices for simplicity.

Agriculture and Outdoor Operations

In open or changing environments, permanent installation can be difficult. Farms often combine stationary gates for automatic reads with mobile tools for manual checks or spot counts.

Manufacturing and Maintenance

In industrial settings, RFID ensures traceability and asset control.

Production lines: Fixed units track items as they move through each process stage.

Tool tracking: Mobile devices allow workers to confirm tool presence or perform audits.

Quality inspection: Portable scanners verify components during random checks.

Fixed equipment automates the workflow; handhelds provide flexibility and human verification.

How to Choose

Selecting between the two requires balancing automation, flexibility, and cost.

Automation Level: For unattended, always-on scanning, stationary readers are indispensable. For ad hoc or manual processes, mobile devices are sufficient.

Tag Volume and Speed: High-density, fast-moving environments favor fixed installations; low-volume or scattered items work well with handhelds.

Layout and Environment: If the facility has defined choke points, fixed placement works best. Where the layout changes frequently, mobility wins.

Budget and Labor: Fixed systems reduce labor but cost more upfront; handhelds are affordable but labor-intensive.

Scalability: Permanent installations excel in stable operations; portable ones adapt better to evolving sites.

Technical Considerations

Antenna Design: In stationary setups, antenna gain and positioning strongly influence coverage; in handhelds, compact efficiency matters most.

Power Management: Reliable batteries and efficient power modes are vital for portable units; fixed systems need uninterrupted power or UPS backup.

Connectivity: Permanent readers usually use Ethernet or PoE; handhelds rely on Wi-Fi, Bluetooth, or cellular links.

Environmental Tolerance: Dust, heat, vibration, and EMI must be considered for both, with handhelds requiring extra ruggedness.

Calibration: Regular tuning and verification keep performance consistent as surroundings evolve.

Combining Both Approaches

Most organizations benefit from using both types together.

Install stationary units at strategic points—gates, conveyors, or entryways—to capture most tag events automatically.

Deploy handheld devices for spot checks, exception handling, and mobile searches.

Ensure both share the same RFID standards so data can flow seamlessly into one middleware platform.

This hybrid architecture maximizes automation without sacrificing flexibility.

Common Mistakes to Avoid

Ignoring RF interference from metal or liquids.

Overlooking tag orientation or placement issues.

Failing to plan for power redundancy.

Underestimating the labor cost of manual scanning.

Neglecting regular calibration.

Mixing incompatible readers across different frequencies or standards.

Emerging Trends

Technological progress is narrowing the gap between fixed and portable solutions.

Edge Processing: Both now integrate onboard analytics, enabling local data filtering and real-time decision-making.

Miniaturization: Compact, modular designs allow easier installation and higher mobility.

Mobile Platforms: Robots and drones equipped with RFID readers blend automation with movement.

Improved Batteries and Energy Harvesting: Longer runtimes and lower power demands make portable systems more capable.

Standardization: Unified APIs and protocols enhance interoperability and simplify hybrid deployments.

Conclusion

The debate over stationary versus portable RFID readers isn’t about superiority—it’s about suitability. Fixed systems deliver unmatched throughput and automation in high-volume settings, while handheld tools offer agility and lower entry costs.

In most practical deployments, the ideal strategy combines both: automation for continuous flow, mobility for targeted tasks. As RFID technology advances—with smarter edge logic, better batteries, and more modular designs—the boundary between the two continues to blur.

Understanding how each behaves, where it excels, and how they complement each other is the key to building RFID systems that are not only efficient and scalable, but also resilient and future-ready.