Managing books at a publishing house is far more complex than it seems. From warehouse inventory to shipping logistics, sample copy distribution to return handling, traditional barcode systems often fall short in speed, traceability, and automation. RFID presents a robust alternative—offering real-time visibility, hands-free data capture, and streamlined operational control.

Understanding RFID in the Publishing Context

In RFID systems, data is transmitted wirelessly using electromagnetic fields. A typical setup involves:

RFID Tags (Transponders)

These are embedded in or attached to books, each carrying a unique ID that can be read without line-of-sight. For publishers, UHF (Ultra High Frequency, 860–960 MHz) RFID tags are typically used due to their longer read range (up to 6 meters) and ability to support bulk scanning.

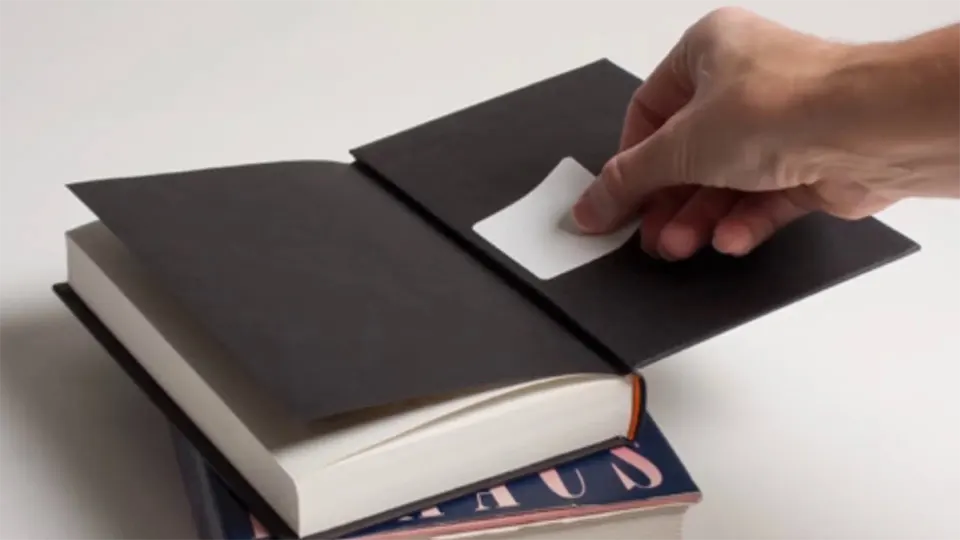

Tag Type: Paper-thin inlays or adhesive labels

Placement: Inside the back cover, spine, or dust jacket

Encoding: Includes ISBN, batch number, print run, or warehouse location ID

RFID Readers and Antennas

These devices emit radio signals to power and communicate with RFID tags. In a publisher’s operations, different types of readers serve different functions:

Handheld readers for shelf inventory and audits

Portal readers at dock doors for shipment verification

Fixed readers in conveyor systems or storage zones

Desktop encoders for tag writing during production

Middleware and Backend Software

RFID data flows into middleware that filters and routes it to a centralized ERP, WMS (Warehouse Management System), or LIMS (Library Information Management System). Middleware handles events such as:

Tag authentication

Location tracking

Movement logs (inbound/outbound)

Data synchronization with print schedules and orders

This ecosystem ensures publishers can manage thousands—or millions—of titles efficiently, with reduced human error and vastly improved visibility across supply chains.

Implementing an RFID Book Management System

RFID adoption is no longer confined to libraries and retailers. Today’s large-scale publishers use RFID to accelerate supply chain logistics, improve print-to-stock workflows, and reduce losses due to misplacement or duplication. Here’s how a typical setup unfolds:

Step 1: Define Objectives and Workflow Mapping

Start with identifying the pain points in your current system:

Manual inventory taking is time-consuming

High error rate in outbound shipments

Difficulty locating sample copies or remainders

Lack of real-time visibility into warehouse stock

Next, map your operational flow: printing → tagging → storing → shipping → returns. This helps determine where RFID should be embedded in the lifecycle.

Step 2: Select Appropriate RFID Tags

RFID tag selection depends on:

Book dimensions and materials

Thin paperbacks require slim, flexible inlays; hardcover books can support thicker tags.

Printing and binding process

Tags must withstand heat, pressure, and adhesives. Some publishers choose pre-encoded tags embedded during printing; others opt for post-print sticker application.

Reading environment

UHF tags are ideal for warehouses and shipping areas, while HF/NFC may be used in demo kiosks or book fairs for interactive marketing.

Recommended tag types include:

Impinj Monza R6 series or NXP UCODE 8 for general item-level tagging

Tamper-evident or metal-friendly tags for special editions

Step 3: Install RFID Readers at Key Checkpoints

Strategically install readers and antennas where tracking matters most:

Encoding Station

A desktop RFID reader/writer is used to encode and verify tag data before books are packed.

Storage Zones

Fixed readers track book movements within racks or bins.

Outbound Docks

Portal readers (RFID gates) scan cartons as they are loaded onto trucks. This eliminates manual scanning of each box.

Returns Handling

Handheld readers quickly scan and sort returned books based on tag ID and status (e.g., re-shelve, destroy, reprint).

Step 4: Integrate with Existing Systems

Integration is crucial. RFID data must be linked to:

Title metadata (ISBN, author, edition)

Inventory counts

Order fulfillment

Print-on-demand records

It’s also important to define business rules:

Auto-alerts if a shipment has missing items

Real-time updates to Amazon or retail partners

Shelf-life tracking for limited-edition prints

Step 5: Staff Training and Pilot Testing

Before full-scale deployment, pilot the system in one warehouse or for a single imprint line. Train warehouse workers, printers, and logistics teams on:

Tag application methods

Reader calibration and positioning

Using handheld scanners for audits

Tag reissuance or duplication handling

A well-run pilot helps reveal integration gaps, system latency issues, and hardware limitations—ensuring smoother scaling later.

RFID Book Tracking at SAGE Publishing, UK

SAGE Publishing, an independent academic publisher based in the UK, faced growing pressure to streamline logistics across their three UK distribution centers. In 2021, they partnered with an RFID integrator to overhaul their book handling system using UHF RFID.

With over 400,000 SKUs and frequent short-run academic prints, their legacy barcode system struggled with:

Inaccurate bulk shipments to universities

High labor costs in inventory checking

Delayed order processing during peak academic months

RFID Deployment

SAGE implemented a full-stack RFID solution:

UHF tags from Smartrac embedded in dust jackets during printing

Desktop RFID encoders at print centers to ensure data consistency

Portal readers installed at all warehouse exits

RFID handheld scanners for bi-weekly inventory sweeps

The system connected to their SAP ERP and reported real-time shipment validation, carton-level tracking, and return detection.

Results & Benefits

Within 12 months, SAGE recorded:

80% reduction in outbound shipment errors

40% time savings in inventory processes

Improved recall accuracy on outdated or withdrawn academic material

Enhanced B2B customer satisfaction due to faster, error-free deliveries

Their logistics team could now pinpoint the location of any title across three warehouses in seconds—a task that previously took hours or required manual audits.

Final Thoughts

RFID is no longer an emerging technology—it’s a mission-critical tool for publishers looking to modernize logistics and compete in a fast-paced content economy. Whether managing millions of SKUs or fulfilling short-run academic titles, RFID brings unmatched speed, accuracy, and intelligence to every stage of the book lifecycle.

From tagging to tracking, publishers equipped with RFID can deliver better service, cut costs, and gain a clearer view of their inventory landscape. As SAGE and others have shown, the ROI is not just financial—it’s strategic. In a sector where timelines and transparency matter, RFID might just be the best chapter yet.