Fixed RFID readers are stationary devices specially designed to continuously scan RFID tags within a defined area. Often installed in critical zones such as doorways, loading docks, warehouse aisles, or retail entryways, these readers form the backbone of automated asset detection and monitoring systems. Unlike handheld readers that require manual operation, fixed readers operate autonomously, enabling real-time tracking and eliminating the need for constant human supervision.

Within this category, there are two main configurations:

Integrated readers, where the RFID reader and antenna are combined into a single compact unit.

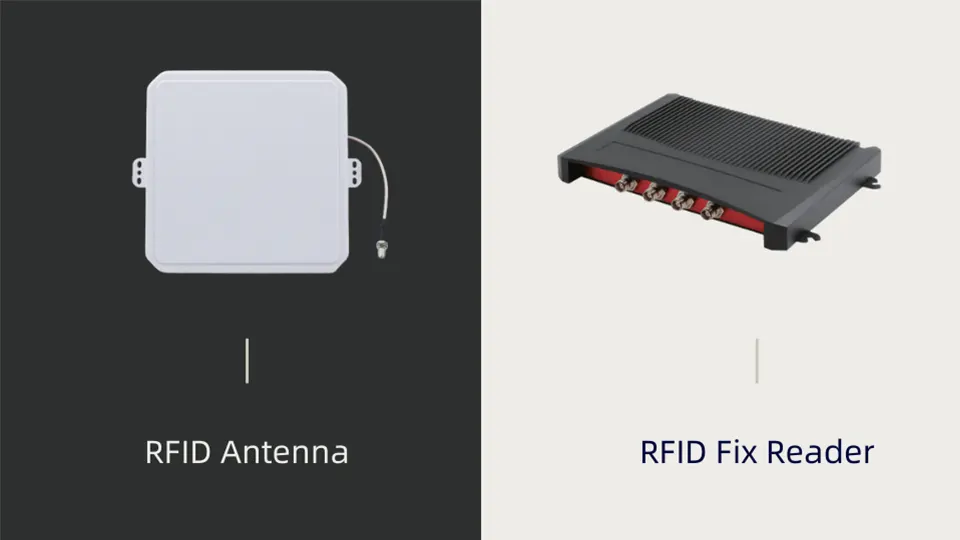

Distributed (non-integrated) readers, where the reader and antenna are separate, connected via coaxial cables.

There’s also a variation known as gateway readers, essentially integrated units optimized for wide-area surveillance in high-traffic choke points.

Integrated vs. Non-Integrated Fixed Readers

Integrated readers merge the electronics and antenna housing, simplifying installation and reducing the system’s physical footprint. Since there’s no cable between reader and antenna, signal loss is minimized, and setup is streamlined. These units are especially useful where space is limited or aesthetics matter, such as retail displays.

However, integrated readers come with limitations. They typically restrict antenna choice and offer minimal flexibility for adjusting read zones. Choosing different beam patterns, polarizations (like circular versus linear), or range specifications generally isn’t possible without replacing the entire unit.

On the other hand, distributed readers place the reader and antennas separately. This architecture enables multiple antennas—up to 32 in some systems—to be deployed, offering expansive coverage across large areas. Designers can mix and match antennas to tailor read patterns, adjust gain, and manage polarization to suit distinct deployment needs. The trade-off is complexity: installation demands careful cabling, mounting, and tuning.

Key Technical Parameters & Interactions

Read Range

Fixed RFID readers, especially in the UHF band, can achieve ranges exceeding 100 feet, considerably more than handheld units. Real-world performance depends on a blend of reader output power, antenna gain, environmental factors, and tag characteristics.

Antenna Gain

Antenna gain directly influences how far signals travel. High-gain antennas (typically 8 dBi or more) extend the read range, while lower-gain versions (7 dBi and below) limit it. Each 3 dB increase roughly boosts range by a substantial margin, often around 40 percent.

Polarization

Linear polarization focuses energy in a single plane, offering longer read range when tags maintain consistent orientation.

Circular polarization radiates in a spiral pattern, ensuring better performance when tag orientation varies, though it may sacrifice some range.

Antenna choice hinges on tag movement: conveyor systems with uniform tag orientation suit linear polarization, while variable orientations benefit from circular polarization.

Frequency Bands

RFID systems commonly operate across three ranges:

Low Frequency (LF, ~125 kHz): Very short range, resilient to interference from metal/liquids.

High Frequency (HF, ~13.56 MHz): Moderate range but more sensitive to environment.

Ultra-High Frequency (UHF, ~860–960 MHz): Longest read ranges and most prevalent for fixed installations.

System Interactions

Whether integrated or distributed, every RFID setup combines a reader (with processing and RF generation) and an antenna (to transmit and receive signals). In distributed systems, reader-generated power travels via cable to the antenna, which broadcasts it; the tag response returns through the same path. Integrated designs eliminate cable losses but lock the antenna configuration in place.

From Planning to Operation

Site Analysis & Planning

Successful implementation begins with understanding the physical layout, asset flow patterns, and target coverage areas. Identifying chokepoints, inventory zones, or areas of frequent interaction helps tailor the reader placement for maximum efficiency.

Antenna Positioning

Antennas might be mounted on walls, ceilings, or shelves—sometimes even hidden within architectural features. Overlapping read zones ensure seamless detection and reduce blind spots.

Choosing the Right Architecture

In tight, controlled spaces—like retail displays—integrated readers make sense. In wide or irregular spaces—like warehouses or production lines—distributed readers offer superior flexibility and scalability.

Configuration & Testing

After physical setup, fine-tuning power levels, read sensitivity, antenna angles, and network integration is essential. Testing with actual tagged items in motion helps verify coverage and minimize interference from neighboring zones or reflections from metal surfaces.

Operational Behavior

Fixed readers continuously scan fast—even scanning dozens or hundreds of tags per second—feeding live data into inventory or tracking systems. This supports real-time stock updates, movement alerts, and immediate location tracking.

Benefits and ROI

Efficiency & Accuracy

RFID far outpaces barcode systems in speed—often by a factor of 15 to 20. Inventory cycles drop dramatically, and multiple tags can be read simultaneously without scanning.

Visibility & Control

Fixed readers enable continuous asset monitoring at strategic points. Whether it’s a warehouse exit, store entrance, or production gate, organizations gain real-time insights into what moves in, out, or stays in a space.

Loss Prevention

In retail settings, fixed readers placed at exits or high-value zones flag tagged items instantly—deterring theft and reducing shrinkage.

Data-Driven Design

Tracking patterns across time can inform layout optimization, stocking strategies, and customer flow analysis—especially powerful in retail analytics.

Cost Effectiveness

Reader units range from entry-level options to high-performance models:

Simple units: a few hundred dollars.

Mid-range models: $500–$1,500.

High-end enterprise-grade units: $1,500–$5,000 each.

Combined with savings in labor, accuracy gains, shrink reduction, and automation, the return often justifies the investment.

Use Cases

Warehousing & Manufacturing

Fixed readers at gates or aisles automate pallet tracking, eliminating manual scanning. They enforce process controls, logging time stamps and movement without human action.

Retail Operations

Retailers mount fixed readers at shelf lines, storage, or checkout zones. This enables automated inventory audits, alert restocking, and even smart self-checkout systems that read whole baskets at once.

Lab & Secure Asset Tracking

In environments like biotech labs or secure facilities, fixed readers track tools, calibration devices, or controlled items. They automate audit trails, ensuring items are logged as they move.

Uniform and Garment Management

Laundry services and hospitals use fixed stations to log return or collection of garments automatically—improving hygiene compliance and inventory accuracy.

Specialized Logistics

In sensitive supply chains—like organ transport or hazardous materials—fixed readers document when items pass control points, reinforcing chain-of-custody and compliance.

Summary Core Components & Dynamics

Fixed RFID Reader – Stationary device (integrated or distributed) that continuously scans tags.

Integrated vs. Distributed – Integrated reads simplicity; distributed enables flexible antenna placement and coverage.

Read Range – Driven by antenna gain, reader power, frequency, and environmental factors.

Antenna Polarization – Linear offers longer range for fixed orientation; circular handles varied tag positioning.

Frequency Bands – LF, HF, UHF each have unique range, interference, and deployment characteristics.

Deployment Workflow – Site assessment → hardware placement → tuning → testing → integration.

Benefits – Speed, automation, visibility, loss control, analytics, ROI.

Applications – Warehouses, retail, labs, uniform tracking, high-security logistics.

Fixed RFID readers and their antennas bring transformative power to modern operations. Whether through sleek, integrated towers or modular, distributed arrays, they supply continuous, automated monitoring that replaces manual, error-prone processes. Their precision, scalability, and adaptability deliver clear value—shortening workflows, improving data fidelity, preventing losses, and enabling intelligent decisions.